Why Emergency Masonry Repairs Can’t Wait in Chicago’s Climate

When masonry fails suddenly, whether from freeze-thaw cycles, hidden water intrusion, or impact damage, you don’t get the luxury of waiting. Chicago buildings take constant punishment from lake winds, temperature swings, aging mortar, and heavy snow loads during the winter. Small failures spread quickly. But moving fast doesn’t mean skipping the steps that protect long-term performance. Emergency work must stabilize the building and set up the correct follow-up restoration, otherwise your “quick fix” becomes a future failure.

What Qualifies as an Emergency Masonry Repair?

Emergency masonry repairs focus on immediate safety and preventing active deterioration.

Typical examples include:

- Loose or falling brick, stone, or terra cotta

- Bowed or bulging masonry walls

- Active water infiltration through cracks or failed sealant

- Rust-jacked steel lintels causing brick movement

- Freeze-thaw spalling or displacement

- Immediate hazards identified by architects, engineers, or city inspectors

In Chicago, inspectors often issue emergency repair notices for unsecured façades or failing lintels, especially after snowstorms or heavy freeze-thaw cycles.

Step 1: Stabilize the Area Safely and Quickly

Emergency crews focus on stabilizing the area to prevent injury or further collapse.

This typically involves:

- Installing temporary shoring

- Removing loose masonry

- Applying temporary sealants or barriers

- Setting up overhead protection (“sidewalk sheds”)

- Coordinating with structural engineers for load assessment

These steps buy time so permanent restoration can be planned correctly.

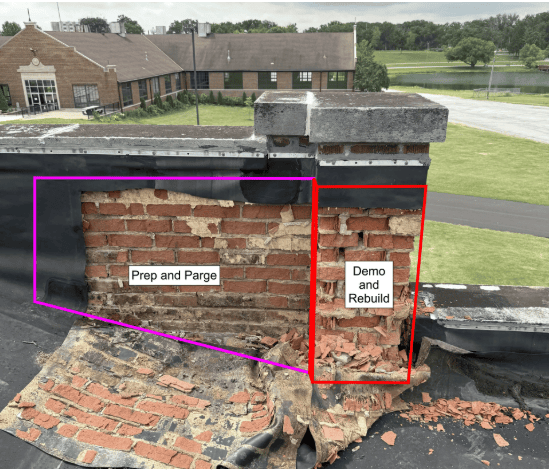

A recent project we did at Meeker Hall in Crown Point required this same approach. Once hidden deterioration around the parapet and roof drains was uncovered, our crew stabilized the affected masonry immediately so roofing work could continue without delays. Quick, coordinated stabilization prevented further water intrusion and kept the project on schedule.

A similar approach was required during emergency stabilization work at the Sheraton Grand Chicago Riverwalk. After impact damage exposed reinforcing steel at the Riverwalk level, the affected areas were secured and stabilized to protect pedestrian traffic and prevent further deterioration in a high-moisture, freeze–thaw environment. This early stabilization allowed permanent concrete and bollard restoration to be planned and executed safely without disrupting hotel or riverfront operations.

Step 2: Identify the Root Cause, Not Just the Symptom

Chicago buildings rarely show symptoms without deeper causes:

- Rust-jacking from steel lintels or shelf angles

- Chronic water infiltration due to failed sealant or flashing

- Insufficient weeps or ventilation

- Historic mortar incompatibility

- Previous improper tuckpointing or patching

A quick visual check isn’t enough. Engineers often review structural connections, moisture behavior, and masonry movement before recommending the right permanent fix.

Step 3: Perform Permanent Repairs That Won’t Compromise Longevity

Depending on the failure, long-term work may include:

- Rebuilding displaced masonry

- Replacing corroded lintels and installing proper flashing

- Grinding and tuckpointing deteriorated mortar joints

- Installing new sealant systems

- Restorative cleaning to remove salts or biological growth

- Replacing damaged brick or structural components

These tasks restore the building to code and stop the cycle of deterioration.

Why “Temporary Only” Fixes Fail, Especially in Chicago

Property managers sometimes get pressured to “hold off until spring” or “patch it for now.”

That usually means:

- Cheap surface patching

- Slapping mortar over damaged joints

- Covering cracks without addressing water intrusion

- Painting over spalls or stains

In our climate, these shortcuts trap moisture and accelerate freeze-thaw deterioration. What starts as a $5,000 stabilization can become a six-figure façade rebuild if delayed.

Chicago-Specific Considerations for Emergency Masonry Repairs

- Freeze-Thaw Cycles: As documented in Energies (via MDPI), repeated freeze-thaw exposure degrades brick and mortar strength and can lead to cracking or spalling.

- Lake Winds: Push water horizontally into masonry openings.

- Historic District Requirements: Historic masonry often uses traditional mortars; preservation guidelines from the National Park Service recommend specific air-entraining mortars to resist freeze-thaw damage.

- Permitting: Emergency work may require immediate notification to the Chicago Department of Buildings, depending on severity.

- Union Labor Expectations: Commercial repair work typically requires certified union craftworkers familiar with façade stabilization and OSHA rigging requirements.

When to Involve a Structural Engineer Immediately

Bring an engineer in right away if you see:

- Movement or displacement larger than ⅛ inch

- Horizontal cracking through multiple brick courses

- Active sagging over openings

- Large gaps around window heads

- Any sign of structural steel corrosion or rust expansion

For emergency failures, property managers should involve a structural engineer who specializes in masonry behavior and understands Chicago’s climate and façade conditions.

Real-World Example

A common scenario in winter: a rusted steel lintel expands, pushes brick upward, and creates cracks that begin leaking during a thaw. The leak leads to interior damage. A property manager calls for “quick caulking,” but the real issue is the steel. Emergency teams stabilize loose brick, install protection, and coordinate with engineers to replace the failing lintel and reconstruct the opening correctly.

How Property Managers Can Prepare Before an Emergency Happens

- Schedule façade inspections before winter.

- Keep a running list of problem areas (cracks, leaks, displacement).

- Maintain a relationship with a restoration contractor and engineer.

- Ensure roof drainage is working; clogged gutters accelerate façade failures.

- Have emergency contact procedures in place for nights/weekends.

According to the CRE Insight Journal, preventative exterior maintenance is essential for ensuring long-term building performance both technically and financially. BOMA International reinforces this in its Guide to Exterior Maintenance Management, which helps property professionals develop preventive and predictive maintenance plans so issues are addressed early, long before they escalate into emergency repairs.

How do I know if a masonry issue is an emergency?

If you see loose or falling material, active water infiltration, displacement around openings, or cracking that appears suddenly, treat it as an emergency. Anything that compromises safety or accelerates deterioration requires immediate stabilization by a professional.

Can emergency masonry repairs be done in winter?

Yes. Emergency stabilization is performed year-round, including during Chicago winters. Many permanent repairs can also proceed depending on temperature, material requirements, and the contractor’s cold-weather procedures.

Should I call an engineer before a contractor?

If the issue involves structural movement, wall displacement, or lintel failure, involve an engineer right away. For leaks, surface spalls, or loose material, a contractor can assess first and recommend whether engineering is required.

How long does emergency masonry stabilization take?

Simple stabilizations may take a few hours; complex or multi-story areas can take a day or more. Permanent restoration depends on scope, material lead times, and weather conditions.

Are emergency masonry repairs more expensive?

They can be, because they often involve urgent mobilization, shoring, and safety setups. But delaying typically increases long-term cost, especially in Chicago’s freeze-thaw climate.

FAQ: Emergency Masonry Repairs

If you have more questions, contact RestoreWorks today.