Why Choosing the Right Masonry Restoration Contractor Matters More Than Ever

Many masonry failures don’t come from bad materials. They come from incomplete investigation, poor sequencing, or repairs that ignore how the building actually performs over time.

In Chicago, this risk is amplified by:

- Repeated freeze–thaw cycling

- Moisture exposure driven by wind and temperature swings

- Historic masonry assemblies not designed for modern sealants or coatings

- Deferred maintenance across older commercial and residential stock

A qualified masonry restoration contractor understands these variables and scopes work to address causes, not just symptoms.

Step 1: Confirm True Restoration Experience (Not Just Masonry Work)

Not all masonry contractors are restoration contractors.

Restoration work requires diagnosing failure mechanisms, integrating multiple façade systems, and working within existing conditions, often while the building remains occupied.

Ask specifically:

- How much of your work is restoration versus new construction?

- Do you self-perform façade investigations and exploratory openings?

- Can you explain how your scopes address water migration, not just visible damage?

A contractor who can clearly explain why a repair is needed, not just what they plan to replace, will typically deliver longer-lasting results.

Step 2: Evaluate Their Approach to Investigation and Mock-Ups

Before final pricing or full construction, a qualified masonry restoration contractor should advocate for investigation and mock-ups when conditions are unknown.

This may include:

- Selective demolition to expose concealed conditions

- Mortar analysis for historic or legacy buildings

- Sealant adhesion testing

- Brick or stone cleaning trials

- Flashing and shelf angle exposure

Mock-ups reduce risk for everyone. They allow teams to validate repair details, cleaning methods, and aesthetic outcomes before committing to full-scale work.

Step 3: Review Their Understanding of Integrated Façade Systems

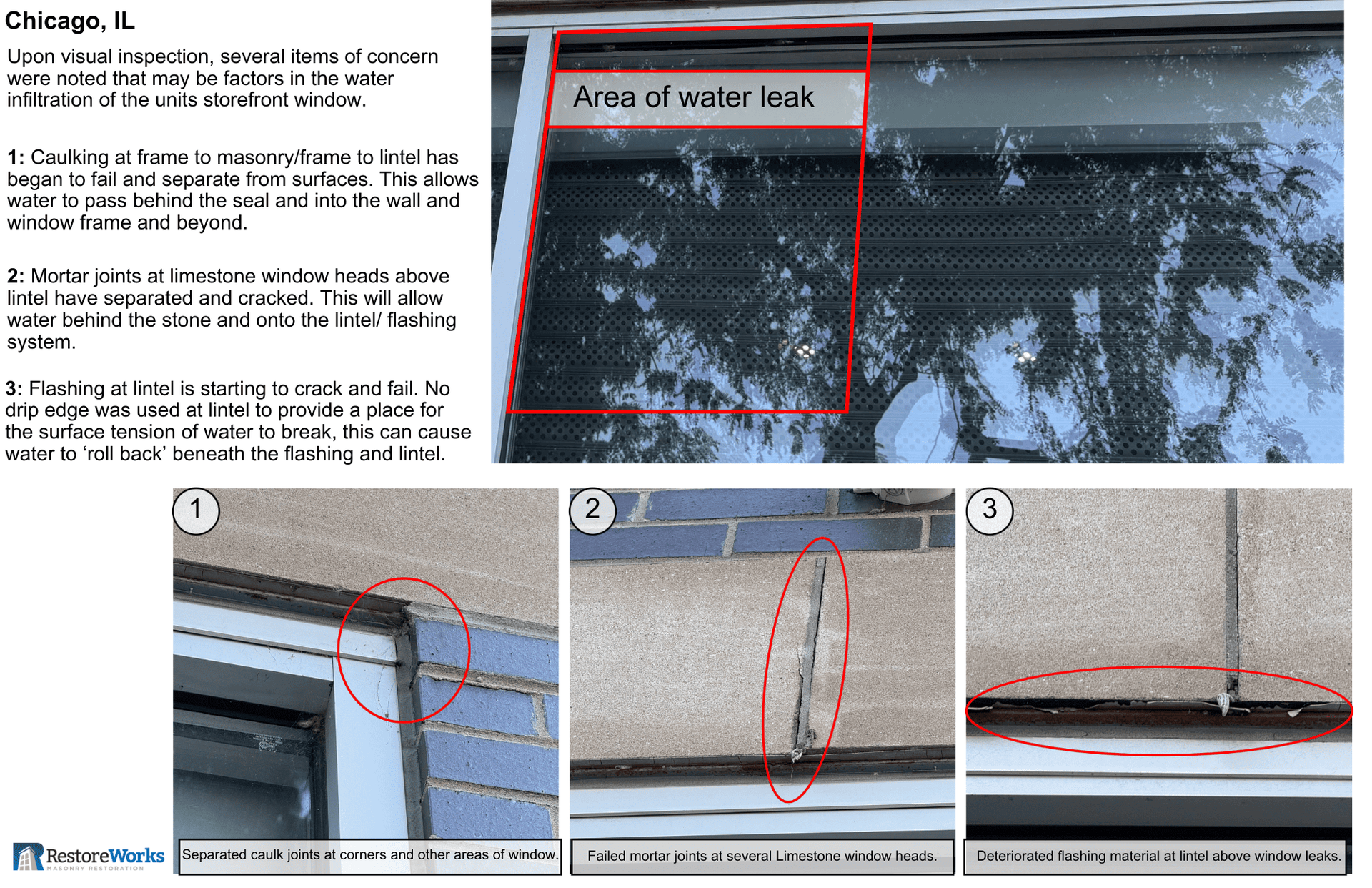

Masonry does not fail in isolation. Water intrusion often involves multiple components acting together.

A competent contractor should demonstrate experience coordinating:

- Tuckpointing and mortar replacement

- Caulking and sealant repairs at windows and joints

- Lintel and shelf angle flashing repairs

- Coping, parapet, and expansion joint transitions

- Concrete façade and balcony restoration where systems intersect

If a proposal only addresses one system without acknowledging adjacent conditions, the scope is likely incomplete.

Step 4: Verify Local Chicago and Regional Experience

Chicago-area buildings behave differently than buildings in milder climates, and not just because of cold weather.

According to the Chicago Metropolitan Agency for Planning (CMAP), northeastern Illinois experiences significant year-to-year climate variability driven by its continental climate. Winters can swing dramatically from cold and snow-heavy to relatively mild, and research indicates this variability is likely to increase over time. For masonry systems, that variability matters more than long-term averages.

Repeated cycles of temperature and moisture fluctuation place stress on:

- Brick, stone, and mortar through freeze–thaw action

- Sealants at windows, expansion joints, and transitions

- Steel lintels and shelf angles exposed to intermittent moisture

- Façade assemblies that were never designed as modern air or moisture barriers

Experience matters when dealing with:

- Lakefront wind-driven rain

- Thermal movement across long façades

- Mid-century construction methods

- Historic masonry assemblies that predate modern air barriers

Ask where the contractor has worked, not just what they’ve done. Familiarity with Chicago-area building types, regional exposure conditions, and local permitting and inspection expectations reduces both technical risk and construction friction.

Step 5: Understand Their Quality Control and Workforce Model

Restoration quality depends on execution, not just specifications.

Key questions to ask:

- Are crews trained specifically for restoration work?

- How is work inspected and documented during construction?

- Who is responsible for field quality control?

- How are safety and access managed on occupied buildings?

For larger or more complex projects, consistency across crews and phases is critical, especially when repairs extend over multiple elevations or seasons.

Step 6: Review Their Long-Term Thinking, Not Just Bid Numbers

Lowest price often reflects the narrowest scope.

A reliable masonry restoration contractor should be willing to discuss:

- Repair prioritization and phased approaches

- Budget-conscious alternatives without sacrificing performance

- Expected service life of proposed repairs

- Maintenance planning after construction

This level of discussion signals that the contractor is thinking beyond the closeout date.

Step 7: Ask for Relevant Project Examples (Not Generic References)

Instead of asking for references alone, ask for examples that mirror your conditions:

- Similar building age and construction

- Comparable exposure and use

- Projects involving multiple façade systems

- Work completed several years ago, not just recently

Experienced contractors can explain what they learned from past projects and how those lessons inform current work.

What Strong Masonry Restoration Contractors Do Differently

- They prioritize investigation before assumptions

- They coordinate masonry, sealants, flashing, and concrete repairs holistically

- They plan work around building use and seasonal constraints

- They communicate risks early, before they become change orders

These are not marketing claims. They are observable behaviors during preconstruction and execution.

Frequently Asked Questions

What’s the difference between masonry repair and masonry restoration?

Masonry repair addresses isolated damage. Masonry restoration evaluates the full façade system (masonry, sealants, flashing, and structure) to resolve underlying causes and extend service life.

Do I need a masonry restoration contractor for tuckpointing?

Yes, if tuckpointing is part of a larger water or structural issue. Improper mortar selection or incomplete detailing can accelerate deterioration rather than prevent it.

Should masonry restoration projects include mock-ups?

For most commercial and historic projects, yes. Mock-ups reduce risk, validate repair methods, and prevent costly revisions once full construction begins.

Have more question? Contact RestoreWorks today.