Building envelope maintenance is most effective when it starts before spring, not after winter damage becomes visible. In Chicago, freeze–thaw cycles, wind-driven rain, and lakefront exposure quietly stress masonry systems all winter long. Waiting until spring often means reacting to failures instead of controlling risk.

Early evaluation gives property managers, engineers, and owners time to prioritize repairs, schedule work efficiently, and avoid emergency conditions when contractors are already booked.

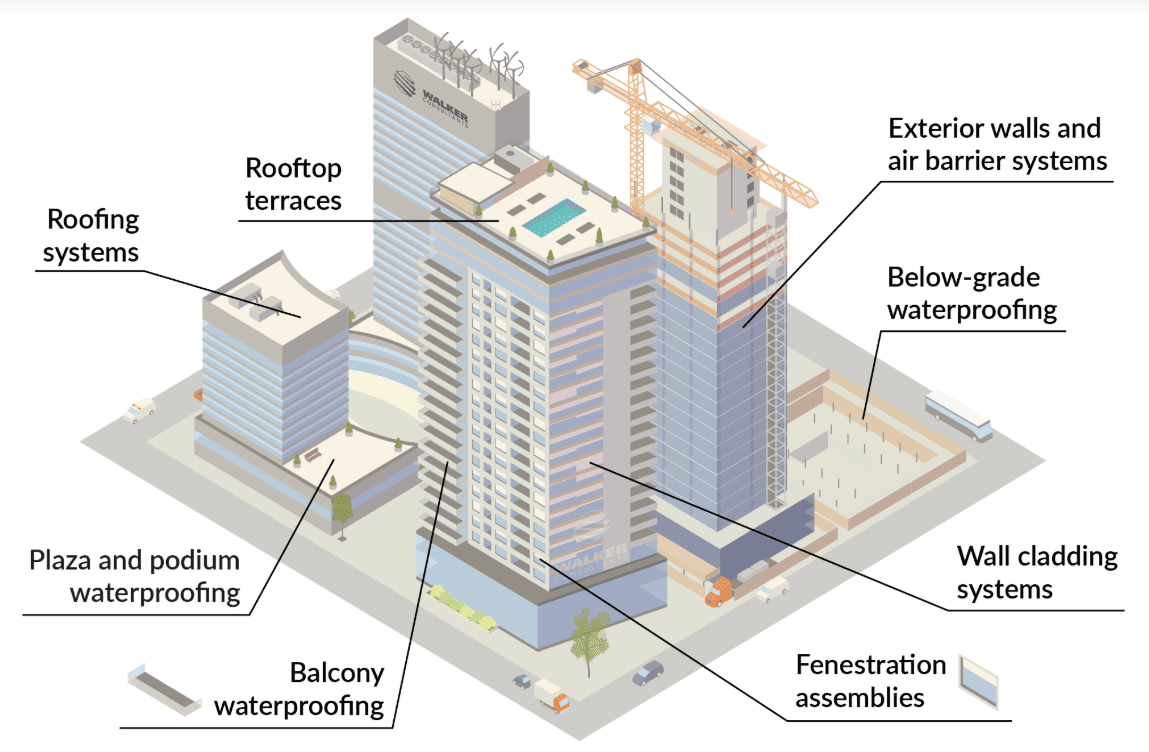

What “Building Envelope Maintenance” Really Covers

The building envelope includes all exterior systems that separate conditioned interior space from the elements. For masonry buildings, that system works as a whole. Failure in one area often leads to problems elsewhere.

Beyond separation, the building envelope also functions as a weather barrier, air barrier, and thermal control layer. Guidance from the National Insulation Association emphasizes that these functions depend on how materials are combined and detailed as a complete assembly, not simply on the performance of individual components.

Typical envelope components include:

- Brick, stone, and concrete façade materials

- Mortar joints and tuckpointing

- Sealants at windows, doors, and expansion joints

- Lintels, shelf angles, and flashing systems

- Balcony slabs, edges, and guard attachments

When these components are maintained together, the building sheds water as designed. When they aren’t, moisture finds paths inward.

Why the Building Envelope Must Be Treated as a System

Industry organizations like the Mason Contractors Association of America (MCAA) emphasize that the building envelope performs best when it is designed, evaluated, and maintained as a system, not as individual components. Mortar joints, flashing, sealants, anchors, insulation, and drainage planes all interact. Addressing one element without understanding its relationship to the others often leads to repeat failures and hidden moisture paths.

This system-based approach is especially important in climates like Chicago, where freeze–thaw cycles and wind-driven rain expose weaknesses across the entire wall assembly, not just at visible failure points.

Guidance from the American Institute of Architects (AIA) has similarly emphasized that building envelope performance is largely determined at system interfaces, such as transitions, penetrations, and changes in plane, where control layers must remain continuous. When these interfaces are not clearly detailed or coordinated, even well-performing materials can fail prematurely.

Why Waiting Until Spring Creates More Risk

Winter doesn’t always cause immediate, visible damage. Instead, it accelerates deterioration that shows up later, often during the first heavy spring rains.

Common issues we see when maintenance is delayed include:

- Mortar joints weakened by repeated freeze–thaw cycling

- Hairline cracks expanding as trapped moisture freezes

- Failed sealants losing elasticity in cold temperatures

- Rusting lintels pushing outward on surrounding masonry

By the time spring arrives, these conditions can shift from “monitor” to “urgent,” forcing reactive repairs.

Research published by the National Institutes of Health (NIH) in a Technical News Bulletin on freeze–thaw behavior in concrete and brick assemblies shows that damage is progressive and often accelerates once moisture is allowed to remain within porous materials. As water freezes, it expands and creates internal pressures that can exceed the tensile strength of masonry, leading to cracking that may not be immediately visible. Left unaddressed, these conditions worsen with each freeze–thaw cycle, turning minor vulnerabilities into significant building envelope failures.

How Chicago’s Climate Changes the Timeline

Chicago buildings face unique exposure conditions that make early planning essential:

- Frequent freeze–thaw cycles stress mortar and masonry units

- Lakefront wind and rain drive moisture deep into façades

- Older construction relies on mass masonry, not modern drainage systems

- Seasonal contractor demand spikes sharply in late spring

Addressing envelope maintenance in late winter or early spring positions owners ahead of weather-related failures and scheduling bottlenecks.

Early Maintenance Allows Smarter Repair Decisions

Starting envelope reviews before spring gives teams flexibility. Instead of bundling everything into emergency scope, issues can be categorized and addressed strategically.

This often includes:

- Prioritizing life-safety or water-intrusion risks

- Planning tuckpointing or sealant replacement during optimal weather

- Scheduling lintel or flashing repairs before corrosion worsens

- Coordinating façade access and mock-ups without time pressure

This approach typically reduces both disruption and cost.

Industry insight published by Facility Executive has highlighted that many building envelope failures present early warning signs such as isolated leaks, hairline cracking, or localized staining long before they escalate into major repairs. When these indicators are investigated early, building teams can often identify the true source of the issue and address it with targeted repairs, rather than reacting after damage has spread through multiple envelope systems.

Where Envelope Failures Commonly Start

Most envelope failures don’t begin with dramatic cracks or falling masonry. They start in predictable locations that are easy to inspect early.

Mortar Joints and Tuckpointing

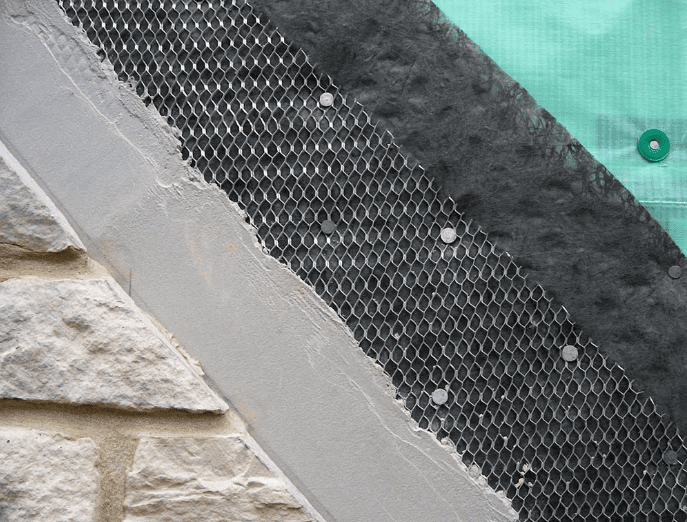

Deteriorated mortar allows water to enter masonry walls. Once inside, freeze–thaw cycles accelerate internal damage.

Sealants at Openings

Failed sealants around windows and doors are one of the most common sources of leaks. Cold temperatures reduce flexibility, leading to separation.

Lintels and Shelf Angles

Steel lintels and shelf angles corrode when moisture reaches them. Rust expansion creates cracking and displacement in surrounding masonry.

Concrete Balconies and Edges

Balcony edges, undersides, and connections are exposed to deicing salts and moisture, making early concrete repairs critical.

Real-World Insight from Chicago Properties

At Calvary Academy in South Holland, Illinois, we saw this pattern firsthand. Interior leaks in bathrooms, hallways, and the library were initially attributed to isolated masonry issues, but investigation revealed multiple contributing envelope failures working together, aging sealants past their service life, hairline cracks in concrete and masonry, failed control joints, and improperly detailed metal copings at the parapet.

Once exterior joint repairs, sealant replacement, and targeted masonry restoration were completed, the interior leaking stopped entirely, before any protective coatings were applied. Addressing the envelope as a system, rather than reacting to interior symptoms, resolved the issue and allowed the school to move forward with a phased, low-disruption restoration plan.

When to Schedule Inspections and Repairs

Late winter through early spring is an ideal window for:

- Visual façade assessments

- Sealant evaluations

- Lintel and flashing inspections

- Planning mock-ups and test repairs

This timing allows work to begin as soon as conditions are suitable, without rushing decisions.

FAQ: Building Envelope Maintenance Before Spring

What is building envelope maintenance?

Building envelope maintenance involves inspecting and repairing exterior systems like masonry, mortar joints, sealants, flashing, and concrete to prevent water intrusion, air leakage, and structural deterioration.

When should building envelope maintenance be done in Chicago?

In Chicago, evaluations should begin in late winter or early spring. This allows teams to identify freeze–thaw damage early and schedule repairs before spring rains expose weaknesses.

What are the most common building envelope repairs?

Common repairs include tuckpointing deteriorated mortar, replacing failed sealants, repairing rusted lintels and flashing, and addressing cracked or spalled concrete façades and balconies.

Can envelope maintenance reduce emergency repairs?

Yes. Proactive maintenance significantly reduces emergency conditions by addressing vulnerabilities before they escalate into leaks, falling masonry hazards, or structural concerns.

Have more questions about building envelope maintenance? Contact RestoreWorks today.