The Challenge

Calvary Academy, a private school in South Holland, Illinois, was experiencing progressive exterior deterioration across its masonry and concrete facades. Years of weather exposure had led to hairline cracking, control joint failures, ineffective sealants, and improperly overlapping metal copings as well as a hastily repointed brick parapet wall. During inspection, water staining was observed on the gym floor and interior walls, with active leaks affecting the boys’ and girls’ bathrooms, hallways, and the library. Damage at the bathrooms and library areas stemmed from the improper joint preparation prior to repointing of the brick parapet wall above those areas while hallways, gym wall and floor damages were due to joint sealants being past their serviceable lifespans, hairline fractures and metal copings not having the proper overlap. These issues compromised water management and raised long-term concerns about facade durability and interior performance.

With multiple elevations requiring attention and ongoing school operations to consider, Calvary’s leadership needed a phased solution that would be minimally disruptive, technically sound, and built to last.

The Solution

Our team developed and executed a two-year restoration plan that prioritized long-term performance, safety, and efficient project staging.

Phase 1 – 2024 Work

East Elevation Focus:

- Concrete & Joint Repairs:

- Repaired surface cracks (~1/16" wide).

- Replaced failing control joints using Sikaflex®-15 LM, a low-modulus, high-movement joint sealant ideal for dynamic wall conditions. It also provides a paintable surface.

- Sealant Upgrades:

- Replaced window and door frame to masonry perimeter sealants.

- Installed DOWSIL™ 123 Silicone Seal pre-formed strips at metal coping joints for clean, reliable expansion joint sealing, including on the gym’s south elevation. We provided the DOWSIL as a semi-permanent repair and let them know that the copings should be addressed by a roofing contractor.

- Masonry Restoration:

- Ground and repointed brick and CMU as marked on east elevation.

- Installed new caulking at roof flashings transitioning between masonry and asphalt shingles.

- Stair Tower Repairs:

- Repointed CMU stair towers where mortar failed.

- Replaced damaged units (up to 3 per tower) and installed retrofit weeps at entry door lintels.

- Protective Coatings:

- Partnered with

Ascher Brothers, a trusted union painting subcontractor, to apply two full coats of Modur Elastomeric Coating by

Sherwin Williams to concrete walls and CMU towers.

- After we did our repairs, we washed the building with Prosoco 2010 All Surface Cleaner.

Phase 2 – 2025 Work

North, West, and South Elevations:

- Repeat Base Repairs: Concrete crack repair, control joint and sealant replacement, and wall cleaning across north and west elevations using the same proven materials and approach.

- Stair Tower Repairs (South Elevation):

- Same scope as 2024 with localized repointing, block repair, caulking, and weep installation.

- Painting:

- Ascher Brothers returned to apply Modur Elastomeric coatings on all applicable surfaces. A second coat was offered as an add-alt for extended service life.

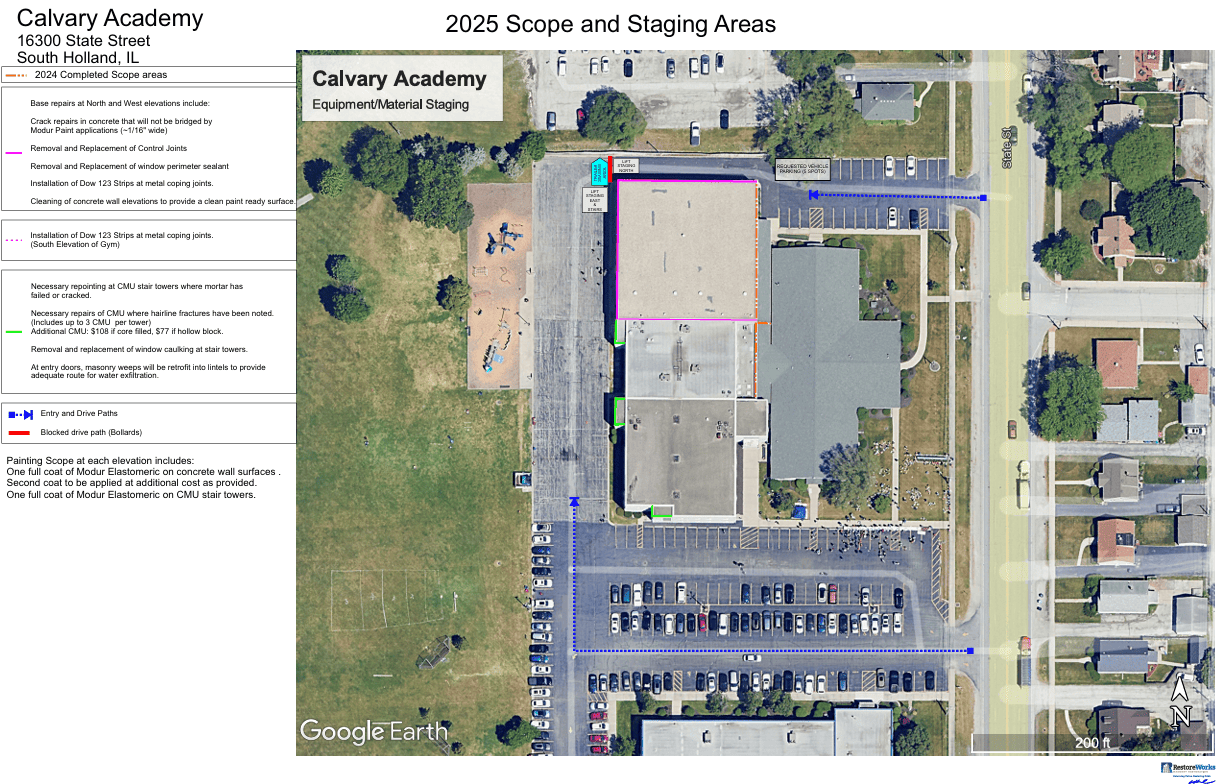

Site Access Coordination:

- Swing stage and boom lift access for the east elevation.

- Drive/parking lane staging for remaining elevations.

- Lift storage planned nightly in northeast or northwest parking lots to avoid interfering with school activities.

Why It Worked

- Durable, Specification-Based Repairs: Use of DOWSIL™ 123 and Sikaflex®-15 LM provided resilient, high-performance joint and sealant systems designed to accommodate movement and prevent water intrusion.

- Phased Strategy: Sequencing the project over two years ensured budget efficiency and allowed ongoing use of school facilities without disruption.

- Union Execution: All masonry and painting work met union standards for safety, quality, and insurance compliance, an essential factor for schools and public-facing facilities.

- Strategic Collaboration: RestoreWorks coordinated closely with subcontractor Ascher Brothers to deliver a smooth, high-quality finish across all coated surfaces.

The Result

The Calvary Academy restoration delivered renewed facade performance with a professional finish, improved water management, and extended material longevity. A thorough inspection by a skilled tradesman with experience in water infiltration allowed us to quickly identify the source of the leaks. Once the crack repairs and joint sealant replacements were completed, the interior leaking stopped entirely. This occurred before the elastomeric coatings and DOWSIL™ 123 strips were even applied. Our union team provided skilled execution and careful coordination from planning to close-out. This project reinforced our commitment to protecting the building envelopes of commercial properties across the greater Chicago area.

Client Feedback

Here’s what Karen Pender, Head of School at Calvary Academy, had to say about the project:

"We recently had the pleasure of working with RestoreWorks on a project that included extensive brick work, masonry repairs, CMU and stair tower repairs, along with replacement of control joints. We couldn’t be more pleased with the results.

From start to finish, the entire crew was extremely polite, hardworking, and attentive to detail. Their professionalism and respect for the property were evident every step of the way.

A special thank you goes to the job foreman, Donnie Zeiger, and Christian Kundel, the project manager, whose conscientious leadership and exceptional attention to detail truly stood out. They ensured every aspect of the project was completed with precision and care, going above and beyond to deliver outstanding quality.

I highly recommend RestoreWorks to anyone in need of expert masonry or structural repair. Their craftsmanship and commitment to excellence are top-notch."