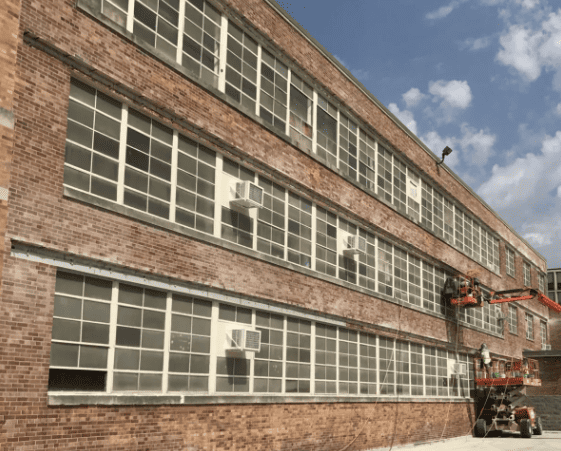

Masonry buildings are known for their durability, fire resistance, and thermal mass, but as they age, their energy performance can decline without regular upkeep. Especially in older or historic structures, even minor deterioration in the building envelope can lead to rising energy costs and occupant discomfort.

Whether managing a mid-century school building or a century-old brick commercial structure, improving energy efficiency doesn’t always require invasive retrofits. In many cases, targeted masonry repairs and maintenance strategies can deliver measurable performance improvements, helping reduce thermal bridging, control air leakage, and limit water infiltration in buildings.

Below, we break down how masonry conditions affect energy use and share tips to improve your building’s thermal performance this year.

Why Masonry Condition Matters for Energy Efficiency

Unlike modern cladding systems with integrated insulation and air barriers, traditional masonry assemblies often rely on the mass of the wall for thermal stability. Over time, however, gaps, cracks, and voids open up, undermining that performance.

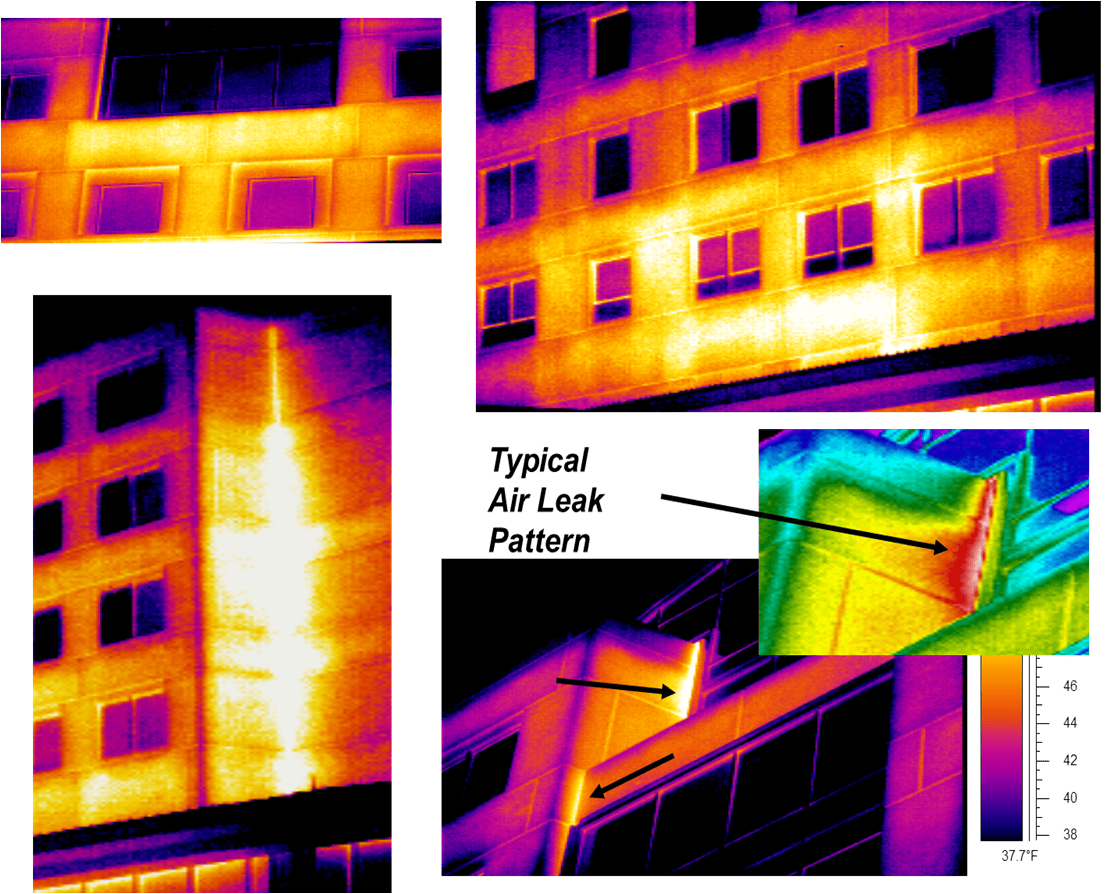

According to ENERGY STAR, air leakage accounts for 25-40% of the energy used for heating and cooling in a typical building. Common leakage paths include gaps around windows and doors, cracks in wall systems, and penetrations for piping or ducts, all of which can exist or worsen in aging masonry structures. Without proactive maintenance, these openings reduce thermal comfort, increase moisture risk, and drive up utility costs.

Common Masonry Issues That Undermine Energy Performance

If your building’s heating or cooling bills are rising (or if tenants report cold spots or drafts) it may be time to inspect for:

- Cracked mortar joints: These allow uncontrolled air leakage and water infiltration, both of which can degrade insulation over time and increase HVAC loads.

- Failed or aging sealants: At window perimeters, control joints, or expansion joints, degraded sealants permit air and moisture infiltration.

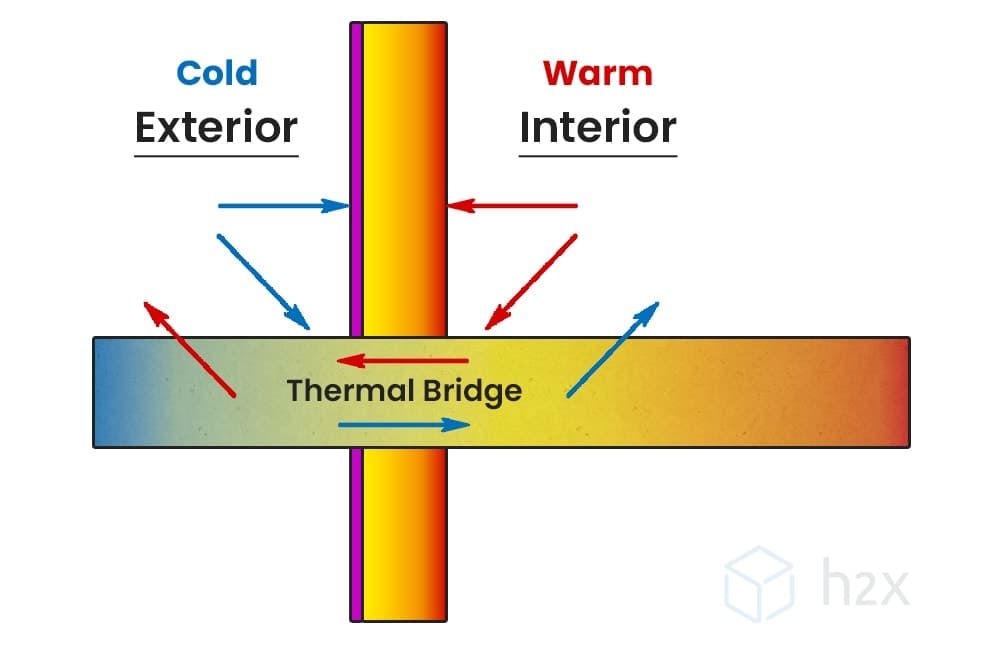

- Thermal bridging: Exposed steel window lintels or concrete shelf angles can conduct heat in or out of the building envelope, especially if not thermally broken.

- Deteriorated masonry units: Spalled bricks or cracked stone can retain moisture and compromise the insulating properties of adjacent materials.

- Lack of insulation behind facades: Many older buildings lack continuous insulation, especially in parapets or cavity walls that have been partially repaired without adding thermal resistance.

- Water infiltration in buildings: Moisture ingress not only damages interior finishes. It also reduces the R-value of insulation, making walls colder and less effective at resisting heat transfer.

Maintenance and Retrofit Strategies That Make a Difference

Proactive masonry restoration is one of the most cost-effective ways to improve envelope performance in aging buildings. Here’s how:

1. Tuckpointing Services

Replacing deteriorated mortar with compatible, tightly packed mortar joints reduces air leakage, seals moisture paths, and restores the thermal integrity of wall assemblies. When executed by skilled tradespeople, tuckpointing can significantly enhance both performance and appearance.

2. Window Lintel Repair and Insulation

Corroded or exposed lintels are not only a structural risk. They also act as thermal bridges. Strategic window lintel repair, paired with insulation upgrades at the head of window openings, helps reduce conductive heat loss.

3. Concrete Lintel Repairs

For structures with precast concrete elements, cracks in lintels or headers can create pathways for air and moisture. Proper crack repair, sealant replacement, and surface protection improves both energy performance and durability.

4. Insulation Additions Behind Facade Repairs

When restoring damaged or cracked masonry facades, take the opportunity to install rigid or spray foam insulation behind rebuilt areas. Even small increases in R-value can lead to measurable energy savings, particularly on north- and west-facing elevations.

5. Sealant and Flashing Upgrades

Replacing perimeter sealants and ensuring flashing is continuous and effective at transitions (such as parapets or window sills) reduces bulk water intrusion and air infiltration.

Checklist: Boosting Masonry Efficiency Without Major Renovation

Here’s a quick reference for facilities teams and building owners looking to improve energy performance through masonry work:

- Inspect for cracked mortar joints and open control joints

- Evaluate sealants around windows, expansion joints, and penetrations

- Check window lintels and shelf angles for rust or thermal bridging

- Identify spalling or moisture-damaged masonry units

- Add insulation during facade repairs where feasible

- Upgrade flashing and weep systems to control moisture

- Review interior comfort issues as clues to envelope failures

- Schedule a professional assessment before winter freeze-thaw cycles

Masonry Restoration in Chicago’s Climate

Chicago-area buildings are exposed to wide temperature swings, wind-driven rain, and frequent freeze-thaw cycles, all of which stress the building envelope. Deferred maintenance only amplifies energy loss. According to Integrity Energy, nearly 30% of the energy consumed by commercial office spaces is wasted due to inefficiencies like aging building systems, poor insulation, and uncontrolled air leakage. These are all issues that proper masonry maintenance can help address.

That’s why masonry restoration plays a critical role in performance planning. Beyond energy cost savings, improving your envelope helps with:

- LEED v4 O+M credits (Envelope commissioning, Air infiltration reduction)

- Meeting newer IECC code requirements for building envelope performance

- Avoiding damage to interior finishes caused by uncontrolled condensation

- Improving tenant comfort and long-term property value

Preserving Historic Masonry While Improving Efficiency

Working on historic masonry buildings requires a careful balance of preservation and performance. RestoreWorks specializes in restoring these structures with minimal visual disruption while upgrading them to meet today’s performance expectations.

We use techniques like custom mortar matching, concealed lintel replacements, and phased insulation integration to protect heritage value while reducing energy loss.

Get Ahead Before Winter

Let us help you identify problem areas before winter hits. Contact us today to schedule a consultation or discuss strategies to improve your building’s thermal performance without costly reconstruction.