If your building is in Chicago or anywhere in the Midwest, you know that fall is a good time to get ahead of the damage that winter can bring. Frost damage caused by trapped moisture and freeze-thaw cycles is one of the most avoidable (yet most expensive) repair scenarios for masonry structures.

Based on field data by the European Geosciences Union, we know that repeated freeze-thaw cycles cause cracking spalling (flaking), and structural weakening of bricks and mortar joints. Most of that damage didn’t start in January either…it started in October, when the signs were overlooked.

Here are five fall maintenance tips to reduce the risk of frost damage and save your spring budget from surprise repairs.

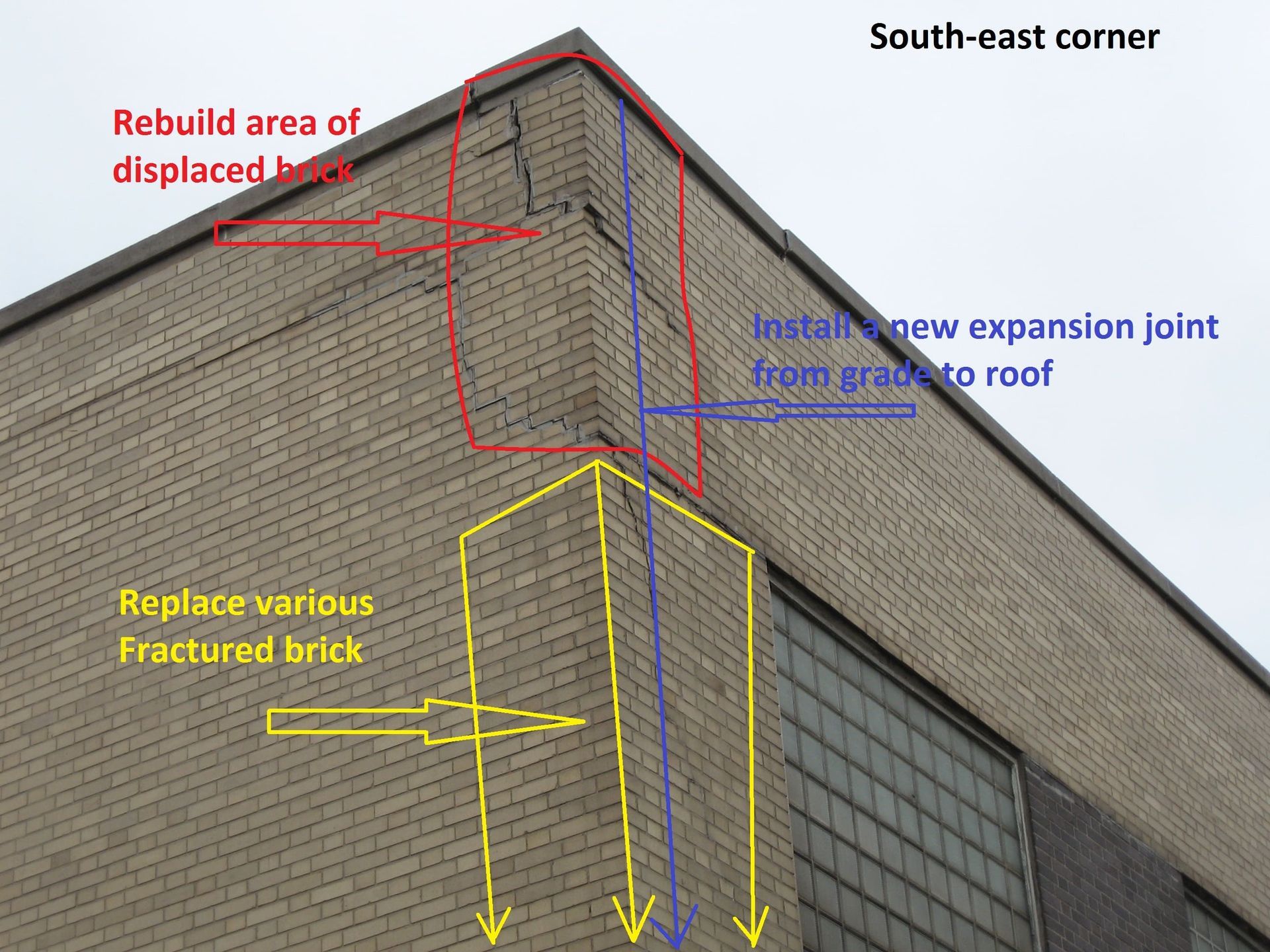

1. Check Control and Expansion Joints Before the First Freeze

It’s easy to overlook joint sealants when walking a façade. But deteriorated or missing sealant at vertical expansion joints or between materials (like where brick meets steel or stone meets precast) is often the first entry point for water.

What to look for:

- Cracked or brittle sealant

- Separation from the substrate

- Sagging or displaced joint filler

A quick visual inspection can help you flag issues, but in multi-story commercial buildings, don’t rely on binoculars from the ground. Use rope access or drone-assisted façade review to get a real look.

Pro Tip: If your team doesn’t have the capacity, a commercial sealant repair contractor can perform a joint audit and reseal before the freeze sets in.

2. Prioritize Repairs on Exposed Concrete Balconies and Parapets

Horizontal masonry surfaces (like exposed sills, parapets, or balconies) are the most vulnerable to frost damage due to standing water and poor drainage. Concrete balconies are especially complicated when the rebar is close to the surface.

Both Cooperator News and the National Association of Housing Cooperatives report that when moisture penetrates concrete and reaches the embedded steel reinforcement, it causes your steel to rust and expand. This internal pressure leads to cracking and spalling of your surrounding concrete.

Recommended actions:

- Patch deteriorated concrete with a vapor-permeable repair mortar

- Address clogged balcony drains

- Add sealant under balcony rail posts

If your property includes aging multi-family or mixed-use buildings, a concrete balcony restoration contractor can tackle these before moisture gets trapped and freezes.

3. Tuckpoint Failing Mortar in High-Exposure Zones

Mortar joints naturally deteriorate over time, but those on windward elevations and above-grade wall caps tend to break down the fastest due to increased exposure. Once weakened, they absorb moisture that expands during freeze-cycles, putting stress on your surrounding masonry and causing it to crack or shift.

Look for:

- Open or recessed mortar joints

- Hairline cracks or spalling on brick faces

- Efflorescence (a sign of trapped moisture)

Tuckpointing doesn’t have to be done across your entire wall. Strategic repair in vulnerable zones can be just as effective. And if your building has a historic designation, using the right mortar mix is key to avoid long-term compatibility issues.

A commercial masonry tuckpointing contractor will understand the importance of matching mortar strength and color for both performance and appearance.

4. Test Drainage and Scuppers for Roof and Facade Runoff

Blocked roof drains or misaligned scuppers can allow water to pool near the base of your structure. Or worse, to run down over brick or stone, which speeds up deterioration.

Before the leaves are fully down, test every component of the drainage system:

- Roof drains and scuppers

- Downspouts and extensions

- Foundation perimeter grading

Poor drainage is a root cause behind many calls we get in the spring about concrete facade repair issues. Most failures involve water entering from above, not below.

5. Inspect and Repair Lintels…Not Just the Brick Around Them

Steel lintels over windows and doors can rust and expand. This cracks the surrounding masonry and allows further moisture intrusion. By the time it’s visible from the ground, it’s already caused displacement.

Fall is the best time to open up questionable lintels and inspect them. If you’re planning an envelope assessment, include spot-checks above openings. This is especially important for buildings over 25 years old.

Depending on your findings, you may need a commercial masonry lintel repair contractor to restore both the steel and surrounding materials before freezing speeds up deterioration.

Final Thoughts

These five actions can reduce your risk of winter-related masonry failure. The data backs it up: ServiceChannel states that top-performing facilities aim for a ratio of 75% proactive vs 25% reactive maintenance, which can have a positive impact on productivity and operational excellence.

If you manage a portfolio of buildings (or oversee complex envelopes), our team can help you identify and address the issues that matter most before the freeze hits. RestoreWorks specializes in commercial masonry restoration with deep experience across multi-use, educational, institutional, and historic buildings throughout the region.

Need a fall inspection or a second set of eyes on a potential issue?

Contact RestoreWorks for a targeted fall assessment. Our team can help you prevent damage before it happens, and make sure your masonry does well through the winter and beyond.