At the Sealant Waterproofing and Restoration Institute’s 2025 Fall Technical Meeting in Boston, RestoreWorks CEO Don Zuidema presented on “Restorative Cleaning Methods: Processes & Best Practices.” The session provided an overview of the three primary cleaning approaches used in masonry restoration, being water, chemical, and low-pressure abrasive, and highlighted how proper selection and execution can protect a building’s envelope while preserving its historic character.

What is Restorative Cleaning?

Restorative cleaning is the controlled process of removing damaging deposits, such as carbon, biological growth, coatings, or graffiti, without compromising the building envelope. When applied correctly, these methods restore masonry to its original appearance and extend the life of commercial properties.

The three main approaches, from least to most aggressive, are:

- Water Cleaning: gentle misting, soaking, or steam.

- Chemical Cleaning: targeted solutions to dissolve stains and coatings.

- Low-Pressure Abrasive Cleaning: controlled media blasting for stubborn contaminants.

Method Selection: Key Considerations

Choosing the right cleaning method requires evaluating several factors:

- Masonry Material (soft vs. hard, porous vs. glazed)

- Soiling Type (carbon, graffiti, coatings, organic buildup)

- Historic Sensitivity (landmark status and preservation requirements)

- Environment (managing runoff, access constraints, adjacent materials)

- Project Scope (timing, sequencing with other trades, and surface prep needs)

Each factor can determine whether a gentle water mist or a more aggressive method is appropriate.

Overview of Cleaning Methods

1. Water Cleaning

- Process: Low-pressure misting, soaking, or steam.

- Best For: Carbon staining, historic masonry, and porous materials.

- Advantages: No chemicals; safe, reversible, and environmentally friendly.

- Limitations: Slower process, often requires repeat cycles.

Case Example - Chicago Athletic Association & Willoughby Tower

At the Chicago Athletic Association, RestoreWorks carefully misted and hand-scrubbed limestone to remove over a century of carbon and grime, restoring the facade without damage.

At Willoughby Tower, a historic skyscraper in downtown Chicago, RestoreWorks employed hundreds of low-pressure misting jets combined with hand brushing. Work was performed at night to minimize tenant disruption, and specialists monitored interior spaces to ensure no water infiltration.

2. Chemical Cleaning

- Process: Acidic, alkaline, or enzymatic solutions applied with strict runoff control.

- Best For: Carbon stains, biological growth, coatings, or paint.

- Advantages: Targeted and effective, can address contaminants water alone cannot.

- Limitations: Requires PPE, careful testing, neutralization, and strict environmental precautions.

Case Example - Art Institute of Chicago

Select chemical treatments were used on stonework at the Art Institute of Chicago to remove accumulated pollutants while maintaining historic detailing.

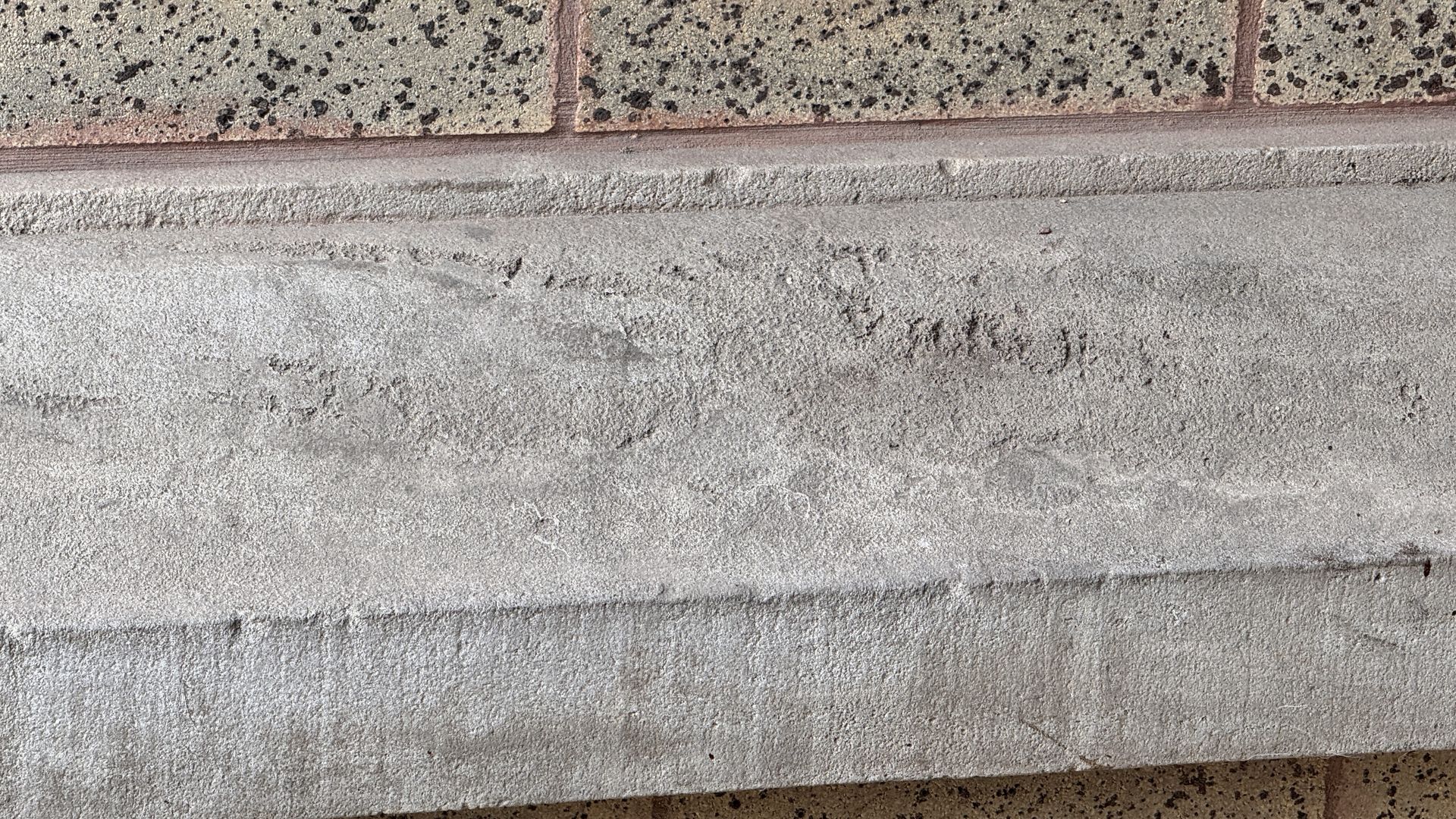

3. Low-Pressure Abrasive Cleaning

- Process: Media blasting using sponge, walnut, glass, or other materials.

- Best For: Graffiti, paint, or heavy surface buildup on hard stone or concrete.

- Advantages: Fast, environmentally friendly, effective for surface-level contaminants.

- Limitations: Risk of surface damage or profiling if misused. Always requires testing by trained operators.

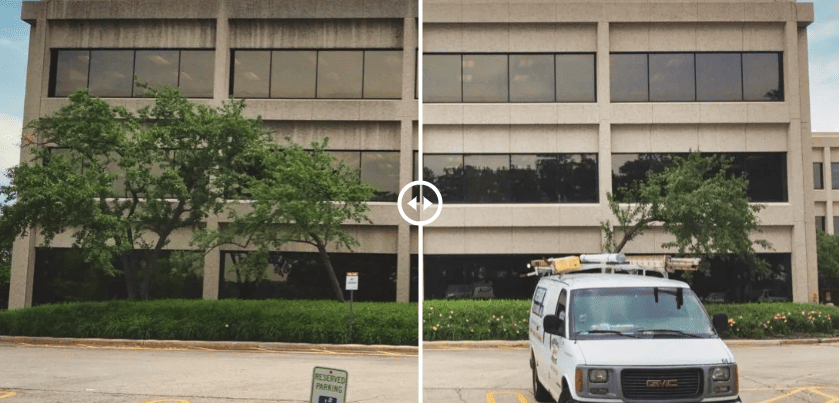

Case Example - McDonald’s HQ, Chicago

Abrasive cleaning restored large facade surfaces impacted by heavy staining at the McDonald’s Headquarters, formerly located in Chicago.

Common Pitfalls in Cleaning

Even the right method can fail without proper execution. Frequent mistakes include:

- Skipping test panels before full-scale cleaning.

- Using the wrong cleaner for the substrate.

- Applying too much pressure.

- Inadequate rinsing or neutralization.

- Cleaning out of sequence with repointing or sealing.

These errors often result in damage, delays, or costly rework.

Best Practices & Final Takeaways

To ensure effective and safe results, RestoreWorks emphasizes the following best practices:

- Start with the least aggressive method that achieves the desired results.

- Always perform mockups and test panels before scaling up.

- Match method to material, soiling, and site conditions.

- Plan sequencing carefully when coordinating with other restoration activities.

- Rely on trained operators who understand both the science and craft of restorative cleaning.

Restorative cleaning is a technical process that requires expertise, planning, and respect for the building envelope. By carefully selecting methods and following best practices, property managers, engineers, and architects can ensure the long-term preservation of historic and commercial structures.

As an experienced Chicago restoration contractor, RestoreWorks continues to lead industry conversations on best practices, bringing practical insights from landmark projects like the Chicago Athletic Association and Willoughby Tower.