At RestoreWorks, we recently co-hosted a hands-on masonry restoration workshop with the International Masonry Institute (IMI) at their training facility in Addison, Illinois. One of the stations during the event focused on Masonry Patching, Dutchman Repair, and Matching/Glaze Repair, an essential set of techniques for restoring damaged stone and terra cotta on historic and commercial structures.

For architects, structural engineers, and property managers tasked with maintaining the long-term performance of aging buildings, understanding these repair techniques is key to preserving both form and function.

Why These Repairs Matter

Masonry Magazine’s article "Historic Masonry Restoration Best Practices," states that understanding the common characteristics specific to each masonry material (such as strength, porosity, water absorption, and composition) is crucial when developing appropriate restoration treatments. This knowledge ensures that repairs not only address visible damage but also maintain the structural integrity and longevity of the building.

The patching and dutchman repair station at our workshop walked attendees through a range of real-world scenarios, providing insights into best practices, common challenges, and material-specific techniques for addressing masonry damage.

Stone & Terra Cotta Patching Techniques

When original units can’t be salvaged, masonry patching becomes a valuable alternative. The workshop emphasized a detailed approach: first patch the missing or damaged section, then shape and sculpt it to match the original profile.

Key considerations:

- Material workability: The patch materials demonstrated were user-friendly, allowing field personnel to sculpt after setting. This is important when detailing ornamental profiles or tight joints.

- Color matching: Because masonry materials like terra cotta and limestone vary widely in color and texture, achieving a good visual match can be difficult. Technicians used layered coating techniques to create accurate finishes, starting with a base color and building up speckling and texture to simulate natural aging.

- Recommended coatings:

- Conproco for terra cotta and limestone

- Jahn M70 for cathedral stone and select historic units

- Permeability concerns: Not all patch materials are created equal. Using a terra cotta patch on limestone, for instance, can hinder moisture transfer. Conproco and Jahn are favored by IMI because they allow the stone to “breathe” and dry naturally, which is important for long-term performance.

Dutchman Repairs: Preserving Authentic Masonry Units

In cases where patching isn’t viable, a Dutchman repair is the go-to technique. This involves removing a portion of the damaged masonry and mechanically anchoring a new piece in place, preserving the majority of the original unit.

Our team demonstrated both stone unit replacement and terra cotta Dutchman repairs, including:

- Creating mock-ups using stone strap anchors

- Preparing dutchmen with precise cuts to blend visually with existing fabric

- Ensuring mechanical anchorage for structural integrity

Dutchman repairs are especially useful on buildings where preserving the original material is a requirement for compliance with local preservation ordinances or historical designations. This is something that frequently applies to Chicago’s landmark buildings and many commercial properties in the greater metro area.

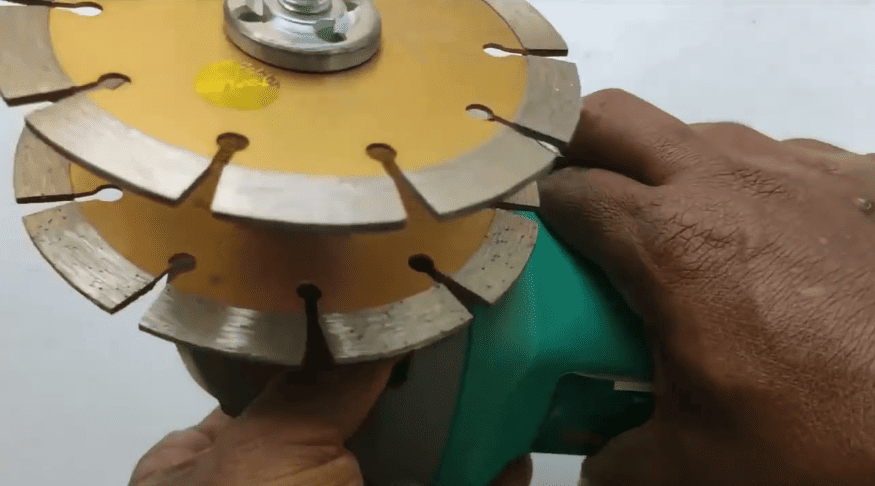

Biscuit Repair vs. Drilling: Installer Perspectives

Attendees were also introduced to biscuit repair, a less technically demanding alternative to full Dutchman methods. Installers favored it for certain conditions because:

- It uses a double-blade grinder to cut a line in the center web of the unit.

- It allows for easier measurement and alignment, making it a more forgiving method for in-field technicians.

- It requires less carpentry skill than precision hole-drilling for plugs or pins.

From a project management standpoint, biscuit repairs can reduce installation time and cost, making them ideal for less visually sensitive areas or large-scale repairs where aesthetics can be blended through coatings.

Matching Matters: Don’t Just Patch. Blend

A key message repeated throughout the station: the repair is only as good as the match.

That means:

- Getting the base color right

- Blending the speckling and natural weathering

- Applying coatings that align with the material’s porosity and finish

Every repair mock-up we demonstrated had a “cut corner” to show the patched section after it had cured and been color matched, an excellent QA/QC tactic that project teams can apply when managing subcontractors.

Final Takeaways for Your Next Project

Whether you're overseeing a multi-family renovation, managing a historic façade upgrade, or navigating pre-bid questions for a large commercial restoration, here’s what to keep in mind:

- Not all patching materials are interchangeable. Match the product to the substrate.

- Coatings are just as important as base patch quality for a seamless blend.

- Dutchman and biscuit repairs each have a place depending on budget, visibility, and durability needs.

- Moisture management is non-negotiable. Use breathable systems whenever possible.

Let’s Talk Masonry Repair Strategy

RestoreWorks specializes in union masonry restoration in the greater Chicago area, with deep experience in both modern construction and historic preservation. Our field teams work closely with architects, engineers, and property managers to deliver solutions that last.

If you'd like to discuss your upcoming restoration project or explore hands-on education opportunities for your team, contact us or check out our latest blog posts on masonry repointing and historic hospital restoration.