Chicago winters are brutal, with temperatures plummeting as low as -22°F in recent years. These extreme conditions put masonry buildings under immense stress, leading to damage that often goes unnoticed until spring. Property managers and building owners who stay ahead of these issues can avoid costly repairs and ensure their structures remain safe and efficient.

At RestoreWorks, we specialize in identifying and resolving winter masonry damage. Here are six common issues to look out for, and how to handle them.

#1. Freeze-Thaw Cycle Cracks

The Problem: Water infiltrates small cracks in masonry, then freezes and expands by approximately 9%, worsening the damage with each freeze-thaw cycle.

The Impact: Chicago experiences an average of 6-7 freeze-thaw cycles annually, a number expected to rise to 11-12 by 2050. These cycles speed up deterioration, leading to spalling and even structural failure.

The Signs: Fine cracks in masonry that widen over time, spalling (flaking or peeling surfaces), moisture stains or discoloration, structural shifts or bulging walls.

How to Prevent It: Regular masonry inspections, prompt crack repairs, waterproofing treatments, and proper drainage can help mitigate freeze-thaw damage.

#2. Water Infiltration

The Problem: Masonry is naturally porous, allowing moisture to penetrate through cracks, mortar joints, and unsealed surfaces.

The Impact: Water intrusion accounts for 40% of all building-related issues. If left unchecked, it worsens freeze-thaw damage, encourages mold growth, and deteriorates interior finishes.

The Signs: Dark or damp patches on walls, efflorescence (white salt deposits), mold and mildew growth, peeling paint or interior wall damage, soft or crumbling mortar joints.

How to Prevent It: Schedule routine inspections, repair cracks promptly, ensure proper drainage, and apply breathable water-repellent sealants.

#3. Efflorescence (White Salt Stains)

The Problem: White, chalky salt deposits appear when moisture within masonry surfaces evaporates, leaving behind dissolved minerals.

The Impact: While not structurally harmful, efflorescence signals moisture issues. According to the Mason Contractors Association of America (MCAA), rainwater is the primary cause of efflorescence in masonry structures.

The Signs: White powdery stains on masonry surfaces, persistent dampness or moisture in affected areas, reoccurring efflorescence despite cleaning.

How to Prevent It: Identify and eliminate water sources, apply protective coatings, and improve site drainage to reduce moisture exposure.

#4. Spalling (Flaking or Peeling Masonry)

The Problem: Water infiltration and freeze-thaw cycles weaken the outer layers of masonry, causing bricks, stone, or concrete to flake, peel, or crumble.

The Impact: Studies show that in deteriorated masonry buildings, spalling affects up to 5% of total wall areas, increasing safety risks and repair costs.

The Signs: Flaking, peeling or crumbling masonry surfaces, pitting or erosion on bricks or stone, loose or falling masonry pieces, exposed interior layers due to surface loss.

How to Prevent It: Repair damaged areas promptly, apply waterproof sealants, and avoid using de-icing salts near masonry surfaces.

#5. Increased Energy Loss

The Problem: Cracks, gaps, and deteriorated mortar joints allow heat to escape and cold air to enter.

The Impact: The U.S. Department of Energy estimates that nearly 30% of energy used in commercial buildings is wasted, much of it due to heat loss during winter.

The Signs: Noticeable drafts near walls, doors, or windows, unexplained increases in heating bills, cold spots inside the building, especially near exterior walls.

How to Prevent It: Seal cracks, repoint mortar joints, apply insulating coatings, and conduct energy audits to pinpoint areas of heat loss.

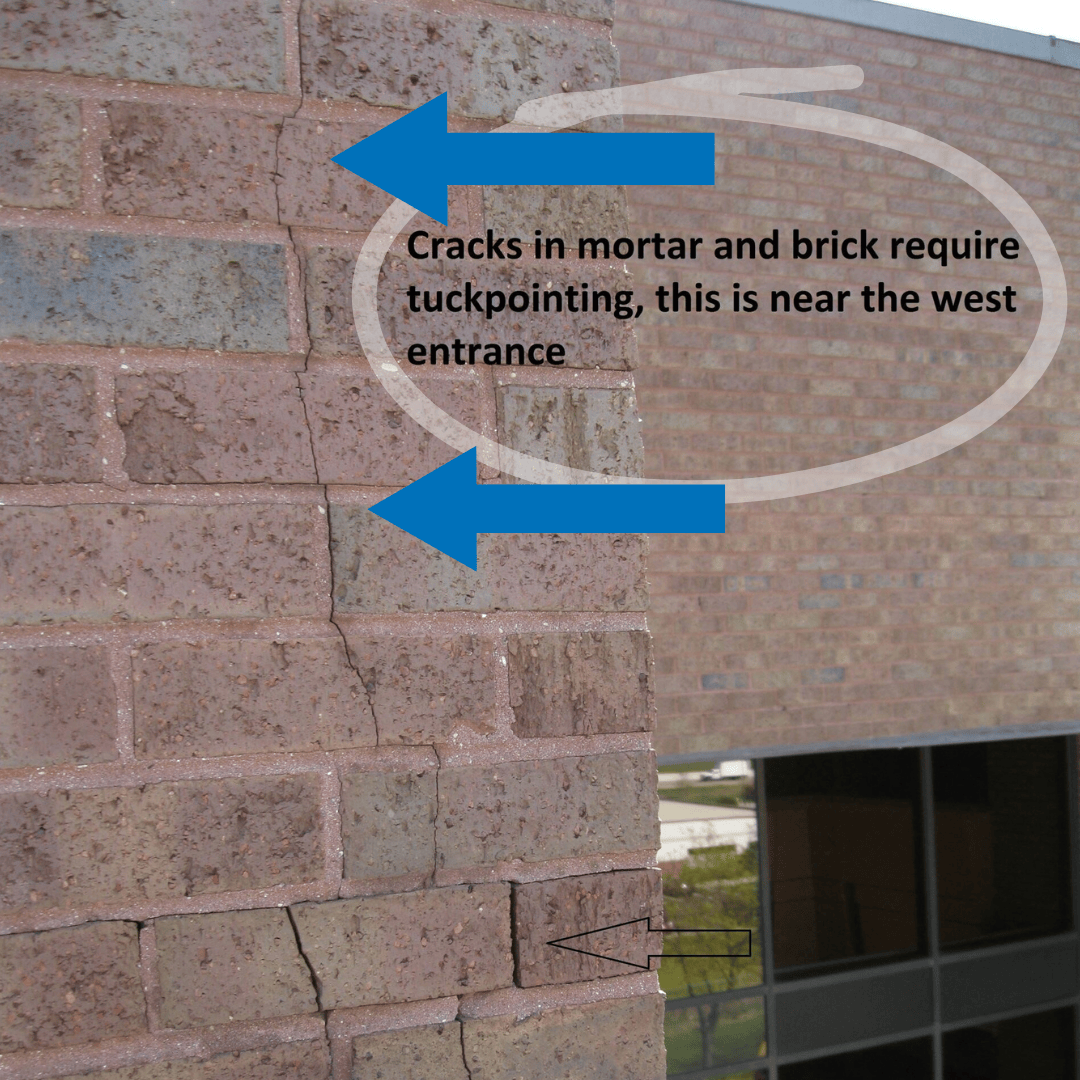

#6. Deterioration of Mortar Joints

The Problem: Freeze-thaw cycles, moisture, and general aging cause mortar joints to crack, crumble, or disappear.

The Impact: According to RILEM, harsh winter conditions significantly accelerate mortar joint degradation, leading to water infiltration, structural instability, and costly repairs.

The Signs: Crumbling or missing mortar between bricks or stones, loose or shifting masonry units, gaps forming between bricks or stonework, water leaks through masonry joints, walls appearing to bulge or sag.

How to Prevent It: Repoint mortar joints, apply breathable sealants, and conduct annual inspections to catch early signs of deterioration.

Protect Your Masonry This Spring

Winter-related masonry issues can compromise the structural integrity, energy efficiency, and appearance of your building. Taking proactive steps now can save you from expensive repairs down the line.

RestoreWorks is here to help. Our union-trained experts specialize in masonry inspections, repairs, waterproofing, and restoration solutions tailored to your building’s unique needs.

Schedule a free consultation today to assess your commercial property’s post-winter condition and get ahead of potential issues.