At RestoreWorks, we pride ourselves on our masonry restoration techniques. Our recent project at the iconic Merchandise Mart in Chicago showcases our expertise in limestone patching. This article delves into the intricate process of preparing and executing flawless limestone patches, ensuring both structural integrity and aesthetic perfection.

The Art and Science of Limestone Patching

Limestone patching is a delicate balance of artistry and technical skill. While matching color, texture, and profile is crucial, the preparation phase is equally, if not more, important. Our team at RestoreWorks understands that proper preparation is the foundation of a successful patch that seamlessly blends with the existing limestone and becomes an essential part of the structure.

Key Steps in Limestone Patch Preparation

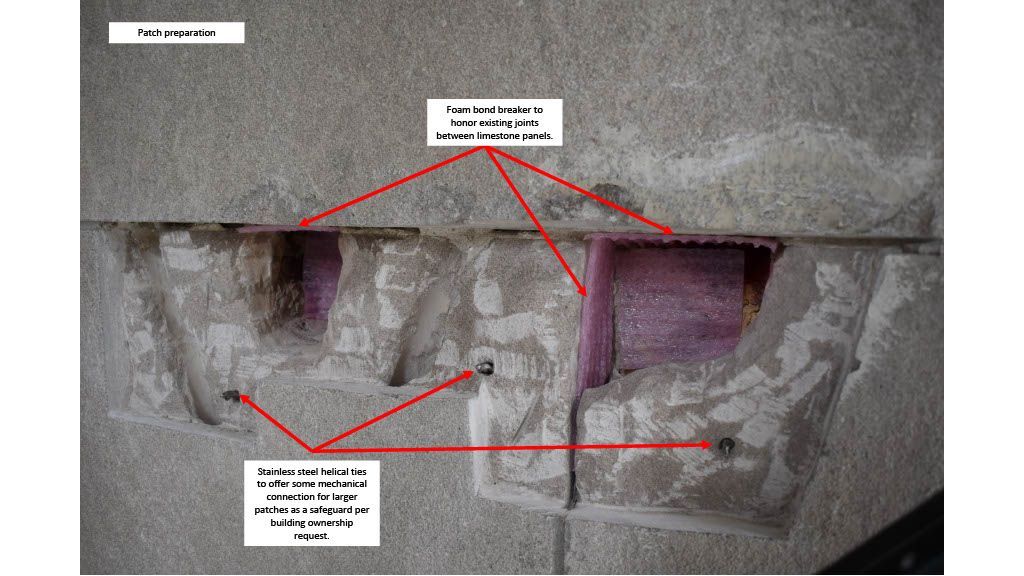

- Squared Edges: We begin by creating clean, squared edges around the area to be patched. This crucial step ensures optimal bonding between the new material and the existing limestone panels.

- Bond Breaker Application: To maintain the integrity of the existing limestone joints, we apply a bond breaker. This technique allows for natural movement between panels, preventing stress and potential cracking.

- Backup Wall Isolation: We isolate the patch from the backup wall using a bond breaker. This separation allows the panel and the wall to move independently, accommodating natural structural shifts.

- Stainless Steel Pinning:

For larger patches, we employ stainless steel pins. These pins provide additional structural support, ensuring the patch remains securely bonded to the existing panel.

The RestoreWorks Difference: Blending Structure and Aesthetics

Our goal at RestoreWorks is twofold: to create a patch that is structurally sound and visually indistinguishable from the surrounding limestone. By meticulously following these preparation steps, we ensure that each patch not only stays firmly in place but also blends seamlessly with the existing limestone facade.

Why Proper Preparation Matters

- Longevity: Well-prepared patches resist weathering and structural stresses, lasting for decades.

- Aesthetic Integrity: Careful preparation allows for better color and texture matching, preserving the building's original appearance.

- Structural Soundness: Our techniques ensure that patches become an integral part of the building's structure, not just surface treatments.

The Merchandise Mart: A Case Study in Excellence

Our work at Chicago's Merchandise Mart exemplifies RestoreWorks' commitment to quality and attention to detail. This historic building, a cornerstone of Chicago's architectural landscape, demanded nothing less than perfection. Our team rose to the challenge, delivering limestone patches that are both structurally sound and visually flawless.

Choose RestoreWorks for Your Masonry Restoration Needs

Whether you're dealing with a historic landmark like the Merchandise Mart or a more modern structure, RestoreWorks brings the same level of expertise and care to every project. Our deep understanding of limestone patching techniques, combined with our commitment to quality, makes us the go-to masonry restoration company in the Chicago area.

Don't trust your valuable limestone structures to just anyone. Choose RestoreWorks for restoration that stands the test of time. Contact RestoreWorks today to learn how we can bring our expertise to your next masonry restoration project.